Since passing the IVA and getting my car registered for road use, I have been working through a number of issues that need to be resolved. Unfortunately these issues need replacement parts, and therefore I am waiting for the PBC, and not doing the miles I was hoping at this stage.

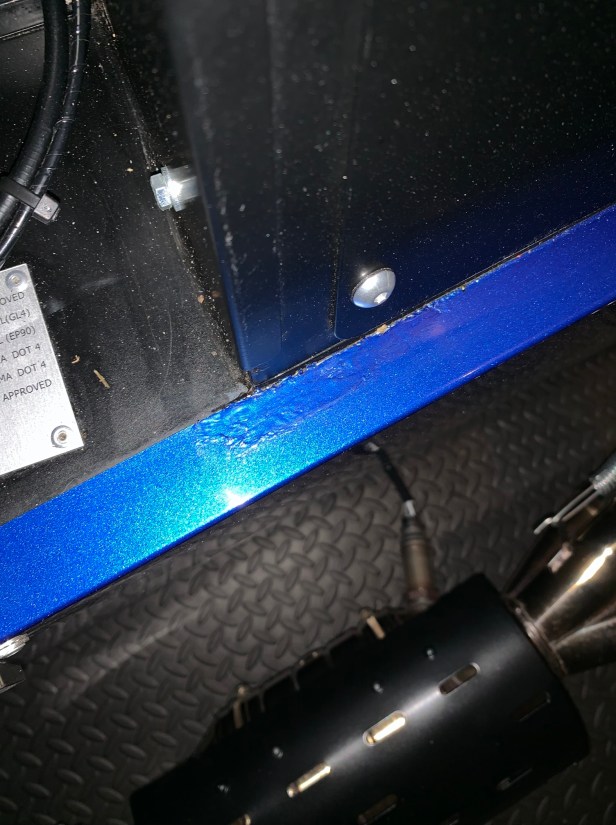

Brake Fuild Leak Damage

Damage Also Underneath

Race Brake Cap

While I wait for the PBC, it’s therefore time to start putting some finishing touches to my build. The first of these touches is to replace the brake fluid reservoir cap with the race brake cap. This cap is supplied with the kit. When fitted, the car won’t pass a MOT or IVA, because there is no low brake-fluid warning light. However, it’s less prone to leaking. Now I know this means I am loosing a piece of safety equipment, but I will be checking my brake fluid level regularly, unlike my daily drive car.

As you can see from the photos, my 360R suffered a leak from the brake fluid cap, and the paint was damaged as a result. Therefore, even with race cap fitted, a rolled up shop towel is secured as a first line of defence against any potential leak.

Brake fluid reservoir socks

Socks for a second line of defence

In addition, I decided to fit brake fluid reservoir socks (or cuffs) thanks to posts on the Caterham & Lotus 7 Owners Group on Facebook. These socks / cuffs have been around for years in the motorbike community, and are designed to protect against leaks, so they are ideal for the job. I realise non-branded versions would be cheaper, but these are way cheaper and far more convenient than fixing paint damage.

I purchased mine from Addiction Motorsport (https://addictionmotorsport.co.uk).

Build Plaque Ready for Fitting

Build Plaque Fitted

Close Up

One of my biggest gripes about Caterham as a kit builder is the lack of a build plaque, which have been fitted to factory built cars for a few years now.

I hatched a plan to create my own version of the factory build plaque. I changed the wording from “Hand Built In Great Britain” to “Home Built In Great Britain”, and obviously personalised it with my own name and signature.

Once I had image files sorted, I got some brushed stainless steel laser etched. Fitting this plaque is simple enough with double sided tape, and this has been a finishing point for my kit build.

Hi Chris

Do you have a link to the guys that did the plate for you

Thanks

Alan

LikeLike

Hi Chris – Do you happen to still have the image file for the plaque? & would you be willing to share it?

Many thanks Richard Dearman

LikeLike

Hi Richard, I do have the file, but it contains paid for artwork. It’s also created using Alinity Designer so you will need a copy of that software. If you use the contact form to ping me, I will give you the details of the company that etched it for me, I believe he can adapt a previously created plaque.

LikeLike

Thanks Chris, no need – I’ve found a local engraver that can do one for me.

LikeLike